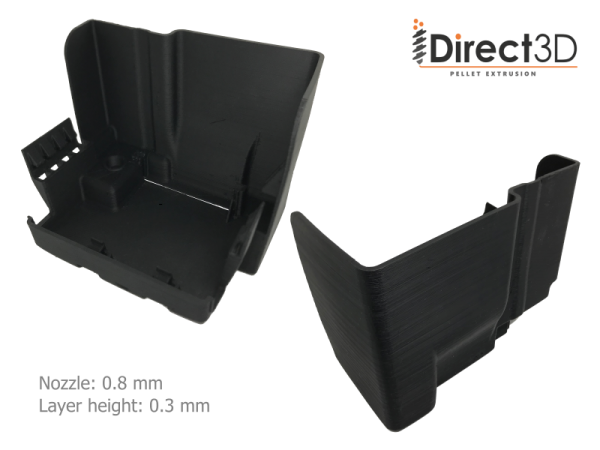

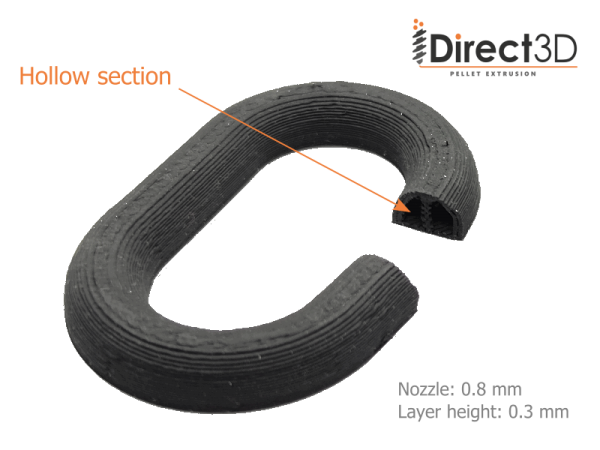

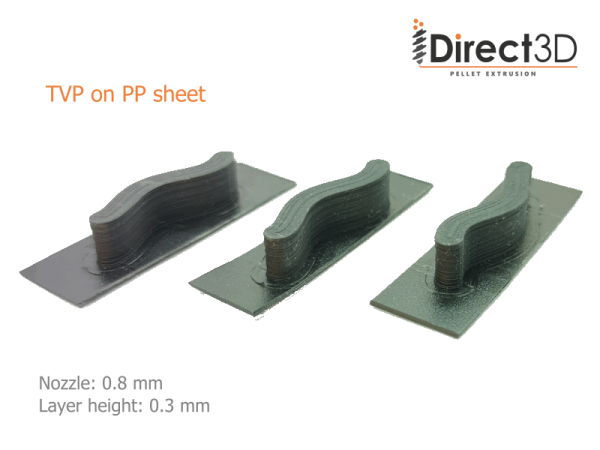

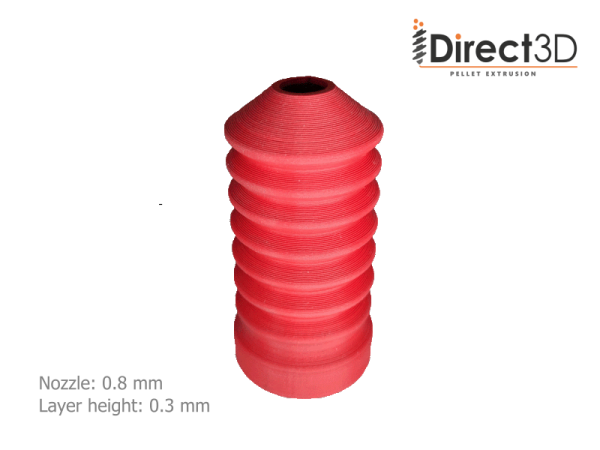

TPE parts production

Direct3D, after months of preparation and joined development with a few key customers, starts its in-house production of parts.

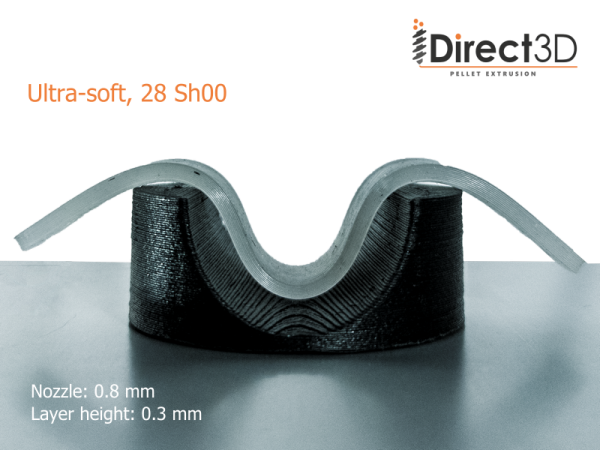

Focus in on thermoplastic elastomers (TPU, TPV, TPS, TPE, TPO, etc), where Direct3D Pellet Extrusion technology allows the use of materials with low hardness, as low as 30 Shore OO, which are a no-go for traditional filament extruders.

Besides, our customers have access to the wide range of thermoplastic products available in the market in pellet form, overcoming another important limitation of traditional 3D printers.

Last but not least, productivity is bigger than with filament extruders, making our process competitive with injection molding for small series production.

Our printing services are also available for single parts (prototyping) and for other materials than TPEs.

Focus in on thermoplastic elastomers (TPU, TPV, TPS, TPE, TPO, etc), where Direct3D Pellet Extrusion technology allows the use of materials with low hardness, as low as 30 Shore OO, which are a no-go for traditional filament extruders.

Besides, our customers have access to the wide range of thermoplastic products available in the market in pellet form, overcoming another important limitation of traditional 3D printers.

Last but not least, productivity is bigger than with filament extruders, making our process competitive with injection molding for small series production.

Our printing services are also available for single parts (prototyping) and for other materials than TPEs.

Previous

Next